Catalogues

Dent Puller & Spot Welder

Dent Puller & Spot Welder Aluminum Dent Puller

Aluminum Dent Puller Combined Dent Puller System

Combined Dent Puller System Double Side Spot Welder

Double Side Spot Welder Inverter Spot Welder System

Inverter Spot Welder System Infrared Painting Curing Lamp

Infrared Painting Curing Lamp Mobile Work Light

Mobile Work Light Battery Charger & Starter

Battery Charger & Starter Hot Stapler

Hot Stapler Induction Heater

Induction Heater Smoke Leak Detector

Smoke Leak Detector Dust Free Sanding Machine

Dust Free Sanding Machine Painting & Storage Racks

Painting & Storage Racks Spares for Sell

Spares for Sell

Product search

Contact details

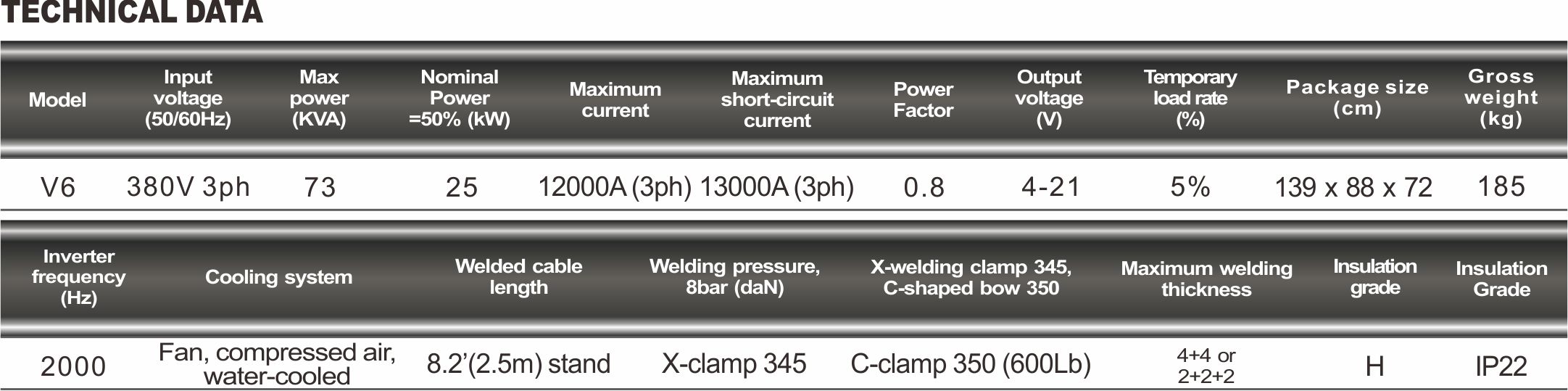

-Inverter Spot Welder System V6-

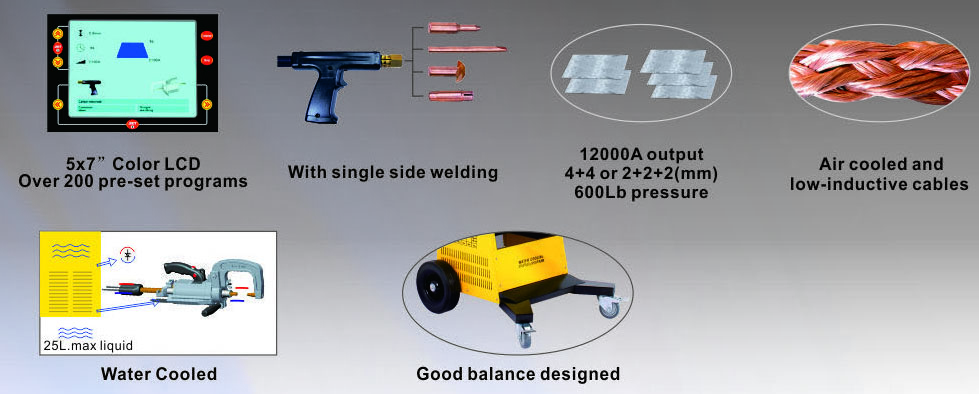

The current and time of all welding functions have been optimised and pre-saved in the computer chip.

When in use, the corresponding buttons, current, and time are automatically set which greatly simplifying the operating program and providing the optimal combination of current and time to ensure the best welding effect.

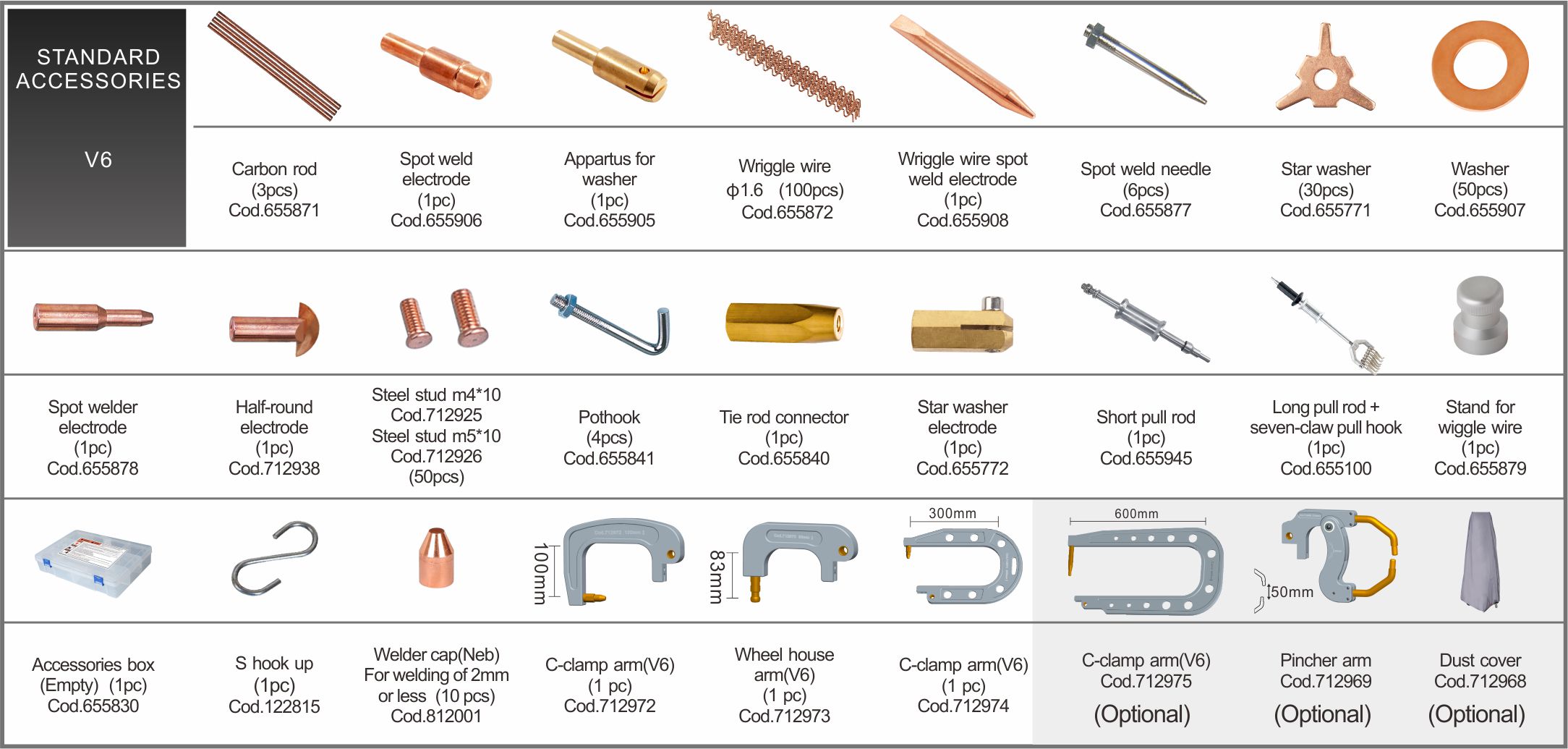

Suitable for meson welding, direct spot welding, carbon rod heating, thin plate repair welding, large area depression restoration, and local heating shrinkage treatment of sand plate depressions.

Equipped with dual pulse welding function, the first pulse is used to preheat the solder joint. The second pulse is used to weld the solder joint, making it highly fused and firm.

The transformer is made of 100% copper wire, which increases the output and continuous working time by 40% compared to transformers made of aluminum wire;

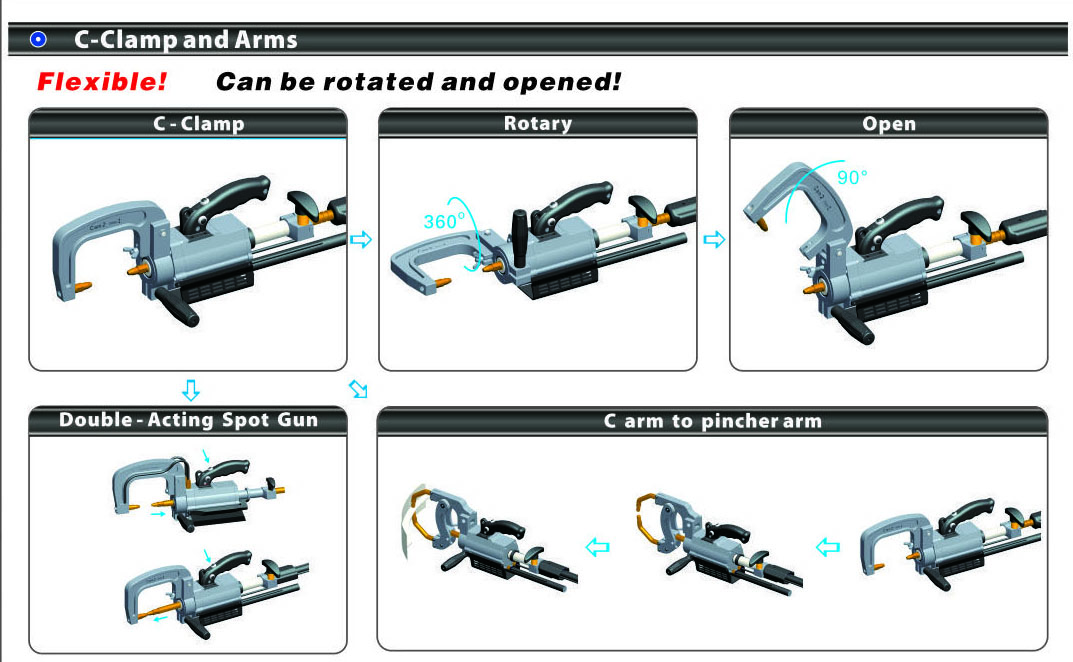

Equipped with dual piston cylinders, the welding arm can be extended to 50cm to ensure strong and reliable double-sided spot welding;

The welding clamp control circuit is advanced and can be controlled to open and close with just one button, making it easy to operate;

Personalised adjustments can be made to the current and time parameters previously present at the factory according to actual needs;

The double sided spot welding pliers are made of high-strength alloy materials, which are both lightweight and durable.

Two digital display windows directly display time and current, beautiful and easy to read.

Provide storage of 3 sets of personalised adjustment parameters for easy of use.

Equipped with double-sided spot welding function

Automatic protection against overheating

Automatic check upon startup